-

Call Us : +86 13728718457

-

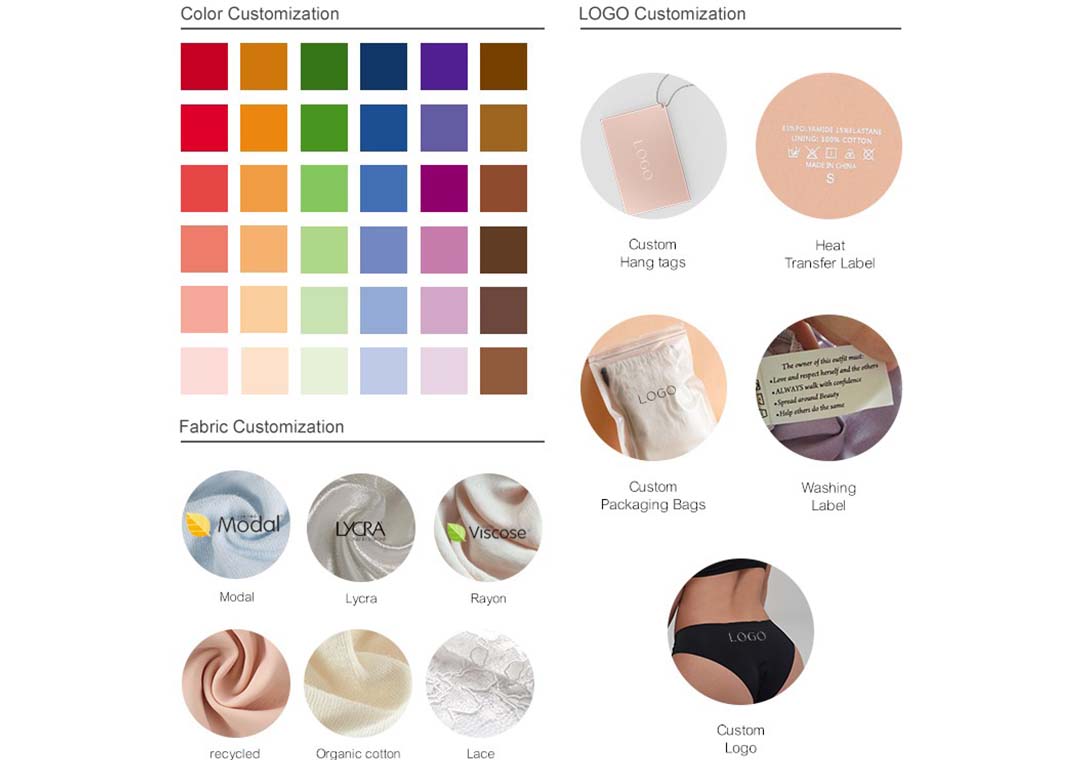

Email Us : Lexie@Sharicca.com

Call Us : +86 13728718457

Email Us : Lexie@Sharicca.com

1.Market demand and style communication

The brand clearly identifies the target market (such as Europe, America/Asia), customer positioning (such as sports underwear/shapewear), price range, and the factory recommends products and production suggestions based on this

2.Select styles and confirm sizes, colors and quantities

3.Provide LOGO and detailed customization requirements,the factory will provide a design draft and sample plan

4.Confirm production schedule, shipping method and delivery date

5.Confirm order, make payment and start production

6.Develop initial samples and obtain sample confirmation

a. Pattern making and first sample development

b. Dress form fitting and pattern adjustment

c. Confirmation of process details

d. European and American live models try on

e. Revision and final confirmation of initial samples

7.Testing and compliance certification

The time required for applying for additional certification is not included in the calculation

a. Product quality and performance testing in the factory's in-house laboratory

b. Compliance certification application (custom certification services are also available to meet special requirements)

8.Pre-bulk production preparation and production implementation

a. Formulation of production process documents and pre-production sample development

b. Material supply chain coordination and production scheduling

c. Quality inspection

9.Factory after-sales follow-up service and market feedback collection

Methods to improve efficiency in Lingerie ODM services((Taking OEM/ODM High Quality Comfy Wireless Seamless Bra as an Example)

1. Determine the target market in advance, select the styles, colors, and quantities for production, and clearly list the customization requirements.

2. Communicate efficiently, clearly specifying production time, shipping time, and payment terms to quickly confirm orders.

3. Cooperate closely to reduce repeated sample modifications.

4. Cooperate closely to quickly confirm sample details and mass production details, and confirm the bulk order.

5. Shorten the payment cycle: Most factories only start production after receiving payment. Therefore, a fast payment cycle is also crucial for improving OEM production speed.

2.Confirm production schedule, shipping method and delivery date

3.Confirm order details, arrange payment and initiate production

4.Develop initial samples and obtain sample confirmation

a. Pattern making and first sample development

b. Dress form fitting and pattern adjustment

c. Confirmation of process details

d. European and American live models try on

e. Revision and final confirmation of initial samples

5.Testing and compliance certification

a. Product quality and performance testing in the factory's in-house laboratory

b. Compliance certification application (custom certification services are available to meet special requirements)

6.Pre-mass production preparation and production implementation

a. Formulation of production process documents and pre-production sample development

b. Material supply chain coordination and production scheduling

c. Quality inspection

7.Factory after-sales follow-up service and market feedback collection

Methods to Improve Underwear OEM Production Speed (Taking OEM & ODM Seamless Leakproof Period Underwear as an Example)

1. Provide a complete tech pack, clearly listing the customization requirements for the period panties, including: production size chart, fabric and accessories, product images, process requirements, functional requirements (e.g., how much liquid absorption is required?), brand logo, style, color, quantity, etc.

2. Efficient communication: Clearly communicate with the supplier regarding required production time, shipping time, and payment terms to quickly confirm the order.

3. Mutual cooperation: Confirm the production details and requirements of the samples with the manufacturer in the early stages to reduce repeated sample modifications.

4. Quick response and cooperation: Quickly confirm sample details and mass production details, and confirm the mass production order.

5. Shorten the payment cycle: Most factories only start production after receiving payment. Therefore, a fast payment cycle is also crucial for improving OEM production speed.

If you want to quickly start your OEM/ODM production, you can contact us:

📩 Email: Lexie@Sharicca.com

🌐 Website: www.chuangrongapparel.com